Automotive industry is and always will be discretely demand driven. While, this demand driven industry solely requires intense productivity outputs and KPI’s. These KPI’s make the production viable and sustainable. Production management, process optimization, cost management create an additional value for the operability of the industry.

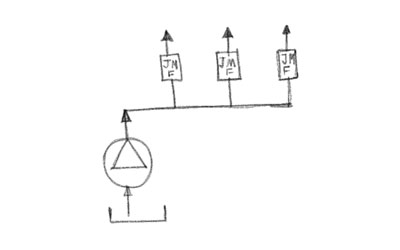

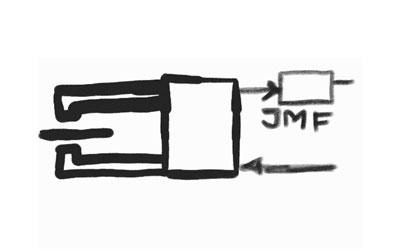

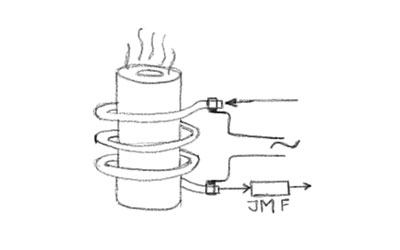

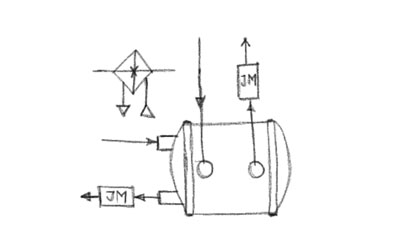

Continuous condition monitoring , mapping the processes and linearizing them with sensor automation can advance the required throughput. Maintenance of critical process parameters like flow, temperature play a key role in obtaining desired results and revenue for the companies and the industries. Technologies which can help in predictive maintenance can help in productive and effective planning and scheduling.